As a truck driver, I’ve always been fascinated by the intricate mechanics that keep my rig rolling down the road. One of the components that piqued my curiosity is the rocker shaft, a crucial element in the valve train of a Detroit DD15 engine. Understanding the correct torque specs for the rocker shaft is vital for ensuring optimal engine performance and preventing costly repairs. So, I dug deep into the world of engine maintenance and discovered a wealth of information about the Detroit DD15 rocker shaft. In this comprehensive guide, we’ll explore the importance of accurate torque specs, the process of tightening rocker shafts, and tips for avoiding common mistakes.

.jpg)

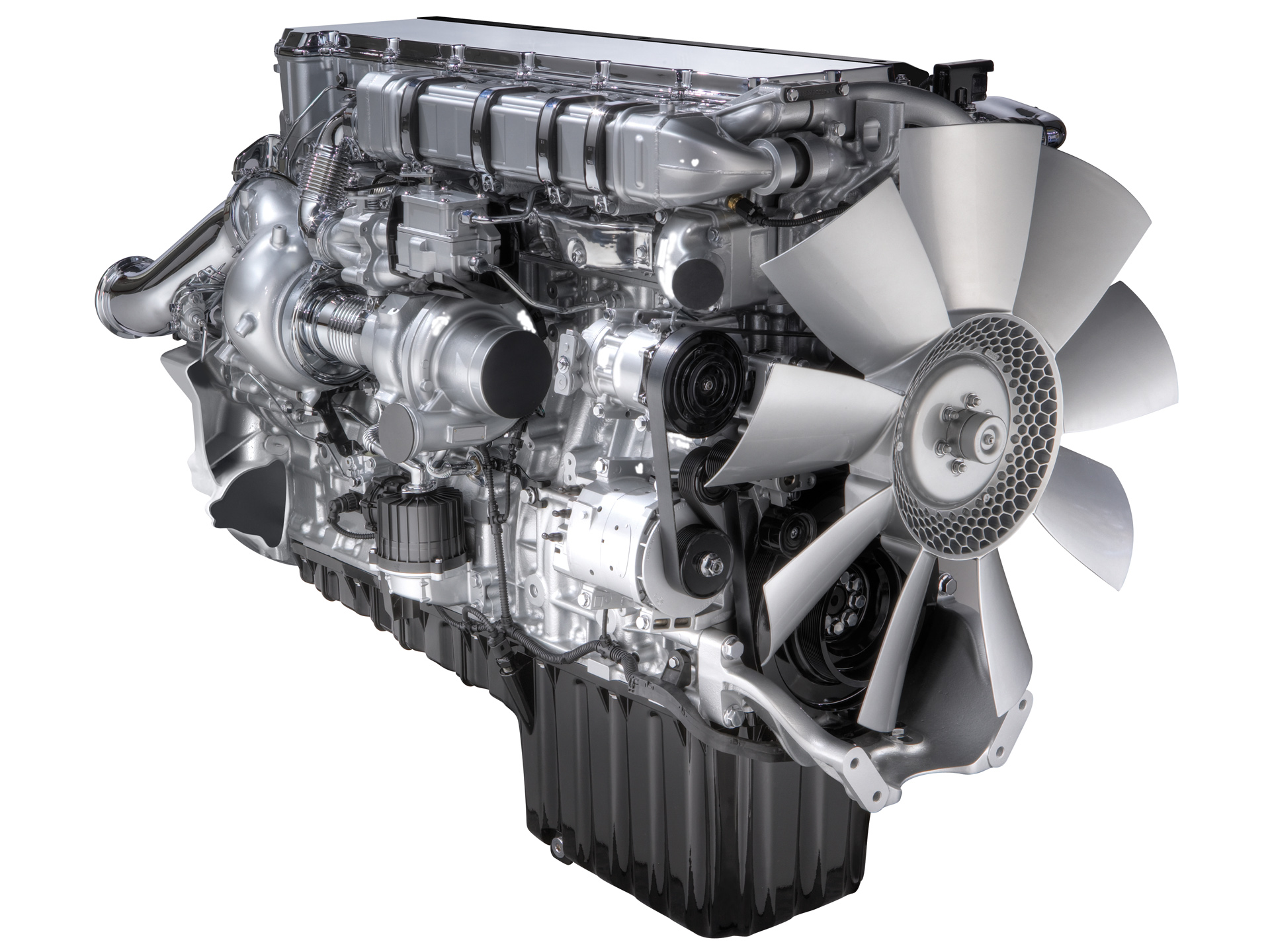

Image: www.heroesdeltimon.com

From my experience on the road, I’ve learned that proper maintenance is essential for maximizing the lifespan of a truck engine. If you’re a truck owner or mechanic looking for information on rocker shaft torque specs for your Detroit DD15 engine, you’ve come to the right place.

Understanding the Detroit DD15 Rocker Shaft Torque Specs

The rocker shaft is responsible for transferring the force from the camshaft to the valves, controlling the timing of intake and exhaust cycles. The rocker shaft itself is a metal bar that sits above the camshaft and is connected to the pushrods, which are connected to the rocker arms, and finally to the valves. Proper torque on the rocker shaft nuts is essential to ensure that the valve train operates smoothly and efficiently. If the torque is too low, the rocker arms can become loose, leading to valve train noise, premature wear, and even valve damage. On the other hand, overtightening the nuts can warp the rocker shafts or damage the valve train components.

The Detroit DD15 rocker shaft torque specs are specific to the engine model and year of manufacture. These specifications are found in the engine’s service manual. It’s crucial to use the correct torque specs, as they are carefully calculated to ensure the optimal balance between clamping force and preventing component damage. If you’re working on a Detroit DD15 engine, always consult the service manual for the precise torque specifications for the specific year and model of your engine.

Importance of Accurate Torque Specs

Accurate torque specifications play a crucial role in the performance and longevity of your Detroit DD15 engine. The rocker shaft is a vital component in the valve train, directly impacting how efficiently your engine operates. When the rocker shaft nuts are tightened to the correct torque, the rocker arms are securely held in place, preventing them from loosening and causing damage to the valve train. This ensures proper valve operation and timing, resulting in smoother engine performance, optimal combustion, and fuel efficiency.

However, if the torque specs aren’t adhered to, it can lead to serious problems that can significantly impact your engine’s performance and lifespan. Incorrect torque can result in loose rocker arms, leading to excessive noise, valve train wear, and potential damage to the valves themselves. Overtightening can also be disastrous, causing rocker shaft warping, premature wear on the valve train components, and even valve train failure. By adhering to the Detroit DD15 rocker shaft torque specs, you’re ensuring the smooth operation of the valve train, contributing to a reliable and efficient engine that performs optimally for years to come.

Detroit DD15 Rocker Shaft Torque Specs: A Step-by-Step Guide

Tightening the rocker shaft nuts is a relatively straightforward process, but it requires precision and careful attention to detail. Here’s a detailed step-by-step guide on how to tighten rocker shaft nuts on your Detroit DD15 engine:

- Prepare the engine: Remove the valve cover to access the rocker arms and valve train components.

- Inspect the rocker arm bolts: Check for any signs of wear, damage, or corrosion. Replace them if necessary.

- Lubricate the threads: Apply a small amount of thread sealant or lubricant to the threads of the rocker arm bolts. This helps prevent seizing and ensures proper tightening.

- Tighten the bolts: Using a torque wrench, tighten the bolts to the specified torque for your Detroit DD15 engine. Consult the engine’s service manual to find the correct torque specifications for your specific year and model.

- Double-check the torque: After tightening the bolts, double-check their torque to ensure they are securely fastened.

- Reassemble the engine: Once you’ve successfully tightened all the rocker arm bolts, reassemble the valve cover and any other components you removed.

Image: www.carsbase.com

Tips for Avoiding Common Mistakes

While the process of tightening rocker shaft nuts seems straightforward, there are common mistakes that can lead to problems. Here are some essential tips to help you avoid these pitfalls and ensure a successful rocker shaft tightening procedure:

- Use a calibrated torque wrench: A torque wrench is essential for applying the correct amount of force to the rocker arm bolts. Ensure your torque wrench is properly calibrated and in good working order.

- Follow the sequence: The rocker arm bolts should be tightened in a specific sequence to distribute clamping force evenly. This sequence is typically outlined in the engine’s service manual.

- Don’t overtighten: Overtightening can cause rocker shaft warping, premature wear, and even damage. Always follow the torque specifications outlined in your engine’s service manual.

- Don’t leave any bolts loose: Ensure all bolts are tightened to the correct torque before reassembling the engine. Leaving loose bolts can result in valve train noise, premature wear, and ultimately, valve damage.

FAQ

To further assist you in understanding Detroit DD15 rocker shaft torque specs, here are some frequently asked questions with detailed answers:

Q: What are the Detroit DD15 rocker shaft torque specs?

A: The Detroit DD15 rocker shaft torque specs vary depending on the year and model of your engine. It is extremely important to always consult the engine’s service manual for the specific torque specifications for your particular engine. Attempting to rely on generic or outdated information can result in engine damage or failure.

Q: How often should I check the rocker shaft torque?

A: As a general rule of thumb, it’s recommended to check the rocker shaft torque during routine engine maintenance. If you experience any unusual engine noises or performance issues, it’s best to inspect the rocker shaft bolts. Regularly checking and adjusting the torque helps prevent premature wear and ensures the valve train functions optimally.

Q: Can I use a standard torque wrench instead of a calibrated one?

A: While a standard torque wrench might seem like a viable option, it’s highly discouraged. A standard torque wrench doesn’t provide the same level of accuracy and precision as a calibrated torque wrench, which is essential for achieving the correct torque specifications. Investing in a high-quality, calibrated torque wrench is a worthwhile investment that ensures the longevity of your engine.

Detroit Dd15 Rocker Shaft Torque Specs

Conclusion

Understanding Detroit DD15 rocker shaft torque specs is crucial for ensuring the proper operation and lifespan of your engine. By adhering to the correct torque specifications, utilizing a calibrated torque wrench, and following proper tightening procedures, you can prevent premature wear, minimize engine noise, and maximize engine performance. Remember, consulting the engine’s service manual is the ultimate guide for finding the precise torque specifications for your specific year and model.

Whether you are a seasoned truck driver or a mechanic, this information will help you better understand the role of rocker shaft torque and the importance of adhering to the correct specifications. Would you like to learn more about the Detroit DD15 engine or other aspects of truck maintenance?